Model:HFD-10

Dryingarea:0.68m2

Processcapacity:11kg/batch

Ultimatevacuum:<2Pa Traysize:315*430(mm)

TrayQty:5pieces pumpingspeed:4L/S

Waterharvestingability:6kg/24hours

supplyvoltage:220V/50HZ (Customiz able110Vor380V)

Packingsize:820*800*1540(mm)

Packingweight:197kg

Power2000w

Processing technology:

The food freeze dryer technology can dry vegetable and fruits, meat and poultry,aquatic products, condiments, convenience and famous specialty products etc and can achieve the purpose of keeping the original color ,aroma, taste,shape and freshness of the food, and it can be reused in the water -based food . Easy to store and transport ,lower cost and keep the nutrition.

Application of fruit vacuum fryer

1. Fruits: apples, kiwi picks, wood grapes, persimmons, strawberries, grapes, peaches, pears, bananas, cantaloupe, pineapple, etc.

2. Vegetables: tomatoes, sweet potatoes, potatoes (fries, potato chips), green beans, shiitake mushrooms, mushrooms, garlic, carrots, green peppers, pumpkins, onions, okra, etc.

3. Aquatic products and meat: small yellow croaker, shrimp, beef, small crab, fish bone, etc.

Advantages of our freeze dryer

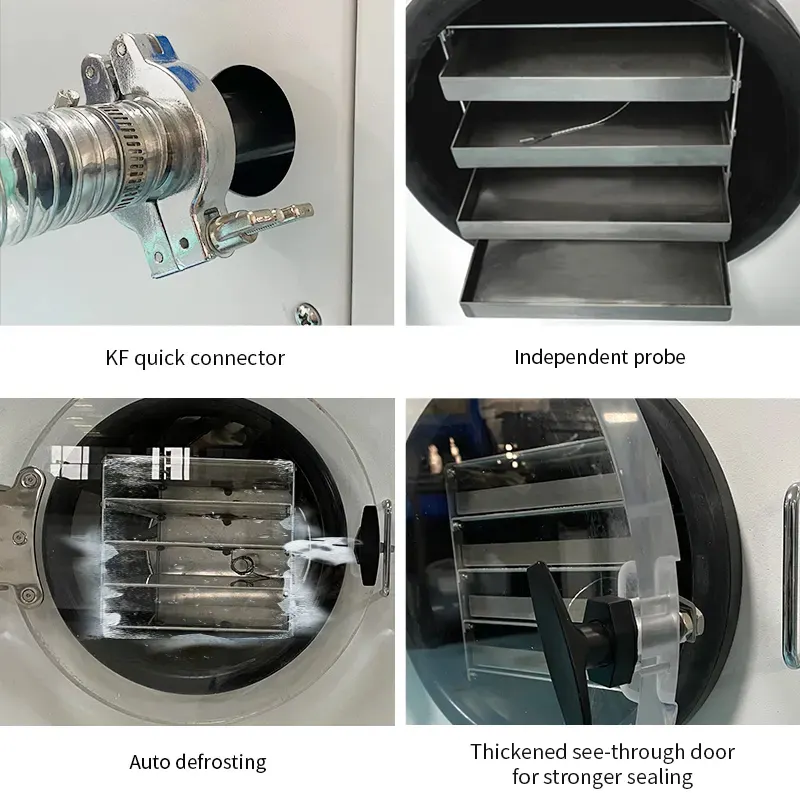

* LCD Touch screen,low noise, large capacity

*The controller is moved to the top left corner for easy operation.

* Automatic one-key start PLC control system throughout the complete freeze drying process

* Oil vacuum pump is included as standard configuration. Oil-free dry scroll vacuum pump is optional.

* Low operating current and low energy consumption

* Solid stainless steel sample tray and chamber reliable for sample safety and easy for cleaning

* Clear organic glass door with direct observation of sample processing

* Optional: stainless steel exterior and oil-free vacuum pump

Working principle of vegetable vacuum fryer:

Prepare fresh vegetables, slice them or cut them into strips,or keep them as whole, then put them in the vegetable vacuum frying machine. In the vacuum system, oil is used as the heat transfer medium to rapidly evaporate the water inside the fruits and vegetables, then the heat enters into materials, so fried materials turn to fluffy and porous tissue structure. Our vegetable vacuum frying equipment can effectively reduce the damage of high temperature to the nutrients of materials to be dried.

Vegetable vacuum frying machine prices are different according to the molds and your materials, please leave us a message for vegetable vacuum fryer price list.

Technical Data:

Please feel free to submit your inquiry information to us. our engineer will contact with you as soon as possible.

The price will be sent soon via email.